What Are Pump Curves? Everything You Need to Know

- Share

- Issue Time

- Oct 21,2025

Summary

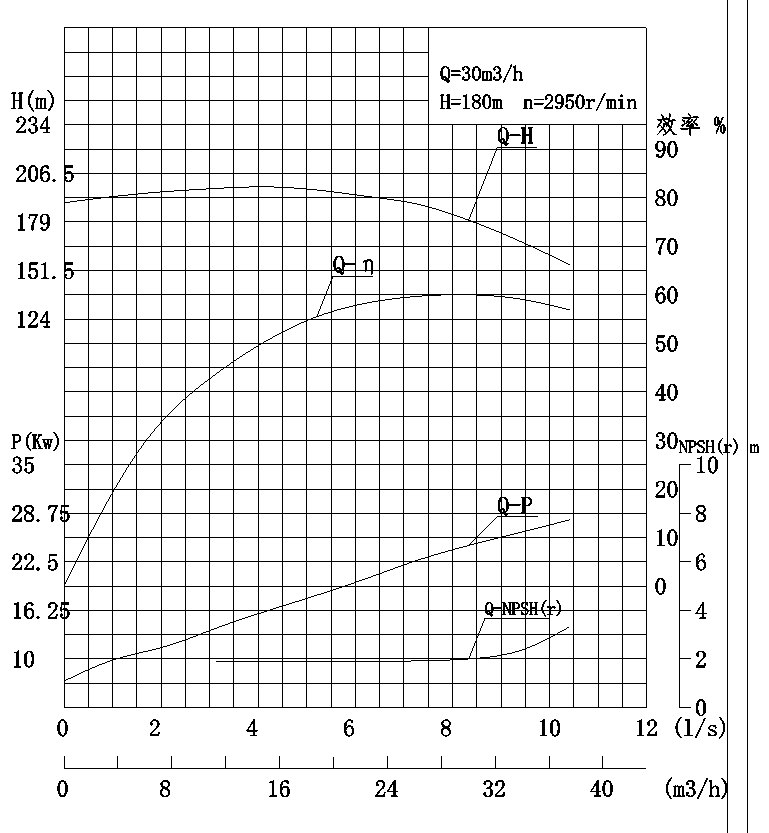

Understanding pump curves is fundamental for effective fluid mechanics and the efficient operation of fluid transfer systems. A pump curve acts as a performance report, visually outlining a pump's behavior under various conditions. Key elements include the Head-Flow (H-Q) curve, illustrating the relationship between flow rate (x-axis) and head (y-axis), supplemented by data on efficiency, brake horsepower (BHP), and Net Positive Suction Head Required (NPSHr). This graphical representation is cru

As we delve into the world of fluid mechanics, understanding how pumps operate is crucial. Today, we're going to explore pump curves – what they are, why they matter, and everything you need to know to decipher them. Pump curves are essentially a pump's performance report card, providing a visual representation of how a pump will perform under various conditions. They are an indispensable tool for engineers and anyone involved in designing or maintaining fluid transfer systems.

Key Takeaways

- What a Pump Curve Is: A pump curve is a graph that illustrates a pump's performance, showing the relationship between flow rate (usually on the x-axis) and head (pressure, on the y-axis). It also includes data on efficiency, power consumption (BHP), and Net Positive Suction Head Required (NPSHr).

- Why It's Essential: Pump curves are critical for selecting the right pump for a specific application to ensure it meets system demands for flow and pressure. Proper selection helps optimize efficiency, reduce energy costs, and prevent premature pump failure.

- Reading the Curve: To read a curve, you find your required flow rate on the horizontal axis and your required head on the vertical axis. The point where these two values intersect is your operating point. This point should be as close as possible to the Best Efficiency Point (BEP).

- Key Components: The main elements you'll find on a pump curve are the Head-Flow (H-Q) curve, power (BHP) curve, efficiency curves (showing the BEP), and the NPSHr curve. Many curves also show different performance lines for various impeller diameters (trims) or pump speeds (RPM).

- Influencing Factors: The performance shown on a standard pump curve is based on water. The fluid's specific gravity and viscosity will alter performance. Higher specific gravity increases the power required, while higher viscosity reduces head and flow and significantly increases power demand. Temperature also plays a role by affecting the fluid's properties and the pump's mechanical components.

What Exactly Are Pump Curves and Why Do We Need Them?

When selecting or operating any industrial pump, understanding its performance roadmap is vital. This roadmap is the pump curve, a graphical chart that shows how a pump will behave under different operating conditions. Without this crucial information, choosing the wrong pump is a significant risk, leading to operational inefficiencies, frequent issues, and expensive downtime. These curves are generated by manufacturers through rigorous testing in controlled laboratory environments, providing engineers with the data needed to predict real-world performance.

The Basics: Defining a Pump Curve

A pump curve is, at its core, a graphical representation of a pump's performance characteristics. It is also known by other names, such as a pump performance curve, characteristic curve, or efficiency curve. The chart plots the relationship between several key variables, but the primary relationship is between the pump's flow rate and the head it generates.

Typically, a pump curve graph displays the following:

- Horizontal Axis (X-axis): This represents the Flow Rate (Q), which is the volume of liquid the pump can move over a specific period. It's commonly measured in gallons per minute (GPM), liters per second (L/s), or cubic meters per hour (m³/h).

- Vertical Axis (Y-axis): This represents the Head (H), which is the energy the pump imparts to the fluid. It's expressed as the height to which the pump can lift the liquid and is usually measured in feet or meters. Using head instead of pressure makes the curve applicable to most liquids, regardless of their density.

In addition to the main head-flow curve, the chart also includes overlaid curves or data points for power consumption, efficiency, and Net Positive Suction Head required (NPSHr), giving a complete picture of the pump's capabilities.

Why Pump Curves are Essential for System Design and Efficiency

Pump curves are not just technical drawings; they are fundamental tools for ensuring reliability, efficiency, and longevity in any pumping system. Their importance stems from several key functions:

Correct Pump Selection: The primary use of a pump curve is to ensure the selected pump precisely matches the system's requirements for both flow rate and pressure. Without a curve, you might choose a pump that is either too powerful (oversized) or not powerful enough (undersized), leading to insufficient performance or wasted energy.

Optimizing Efficiency and Reducing Costs: The curve clearly shows the pump's efficiency across its operating range, highlighting the Best Efficiency Point (BEP). Operating a pump at or near its BEP significantly reduces energy consumption, which is critical because energy can account for as much as 85% of a pump's total lifetime cost. Selecting a pump that will operate far from its BEP can lead to dramatically higher energy bills and a shorter operational lifespan.

Preventing Equipment Failure: Operating a pump at the extreme ends of its curve—either near "shutoff" (zero flow) or "runout" (maximum flow)—can cause severe mechanical problems. These conditions can lead to overheating, excessive vibration, and cavitation, a destructive phenomenon that can quickly damage internal pump components. The pump curve helps engineers design systems that avoid these damaging operational zones.

System Troubleshooting and Maintenance: An existing pump curve can be an invaluable diagnostic tool. If a system is underperforming, maintenance professionals can measure the current flow and pressure to plot the actual operating point on the curve. This helps identify issues such as blockages in the system, component wear, or incorrect operational settings.

Key Elements of a Centrifugal Pump Curve: Unpacking the Data

A centrifugal pump curve is packed with information that describes every facet of its performance. Understanding each element allows engineers and technicians to select the right pump and ensure it operates efficiently and reliably. The primary components displayed on these curves are flow, head, efficiency, power, Net Positive Suction Head Required (NPSHr), and the effects of impeller size and speed.

Flow Rate (GPM or L/s): How Much Liquid Moves?

The flow rate, represented on the horizontal x-axis of the pump curve, indicates the volume of liquid a pump can move per unit of time. This is one of the two primary parameters defining a pump's performance. Common units for flow rate are gallons per minute (GPM), liters per second (L/s), or cubic meters per hour (m³/h).

The curve illustrates the inverse relationship between flow rate and head in a centrifugal pump: as the flow rate increases, the head (pressure) the pump can generate decreases. The flow rate begins at zero, a point known as the shut-off head, where the pump generates its maximum pressure but moves no liquid. It ends at the runout point, which is the maximum flow the pump can deliver at zero head. Operating a pump continuously at either of these extremes can lead to damage.

Total Dynamic Head (TDH): The Pump's Pumping Power

Total Dynamic Head (TDH), displayed on the vertical y-axis, is a measure of the total energy a pump must impart to a fluid to move it from its source to its destination. It's essentially the total resistance the pump has to overcome. Because TDH is expressed in units of length (feet or meters), it provides a universal measure of pump capability that is independent of the fluid's density.

TDH is calculated by summing three key components:

- Static Head: This is the vertical height difference between the starting point of the liquid and its final destination. For calculation purposes, this is always measured as a worst-case scenario, such as from the lowest liquid level in a source tank to the highest point of discharge.

- Friction Loss: As fluid moves through pipes, valves, and fittings, it encounters resistance, which causes a loss of energy. This friction loss is dependent on the flow rate, pipe size and material, and the number and type of fittings in the system.

- Pressure Head: This accounts for any pressure differences between the source and destination tanks. For example, if the pump is discharging into a pressurized vessel, the pump must overcome that additional pressure.

The formula is straightforward: TDH = Static Head + Friction Loss + Pressure Head. A correct TDH calculation is essential for accurately sizing a pump for any application.

Net Positive Suction Head Required (NPSHr): Preventing Cavitation

The Net Positive Suction Head Required (NPSHr) is a critical parameter provided by the pump manufacturer to prevent a damaging phenomenon known as cavitation. The NPSHr curve, typically shown at the bottom of the main graph, represents the minimum pressure required at the pump's suction inlet to keep the liquid from vaporizing due to the low pressure created inside the pump.

Cavitation occurs when the pressure of the liquid drops below its vapor pressure, causing vapor bubbles to form. As these bubbles move into higher-pressure areas within the pump, they collapse violently, creating shockwaves that can erode the impeller and other components, leading to noise, vibration, and eventual pump failure.

To avoid this, the Net Positive Suction Head Available (NPSHa) of the system—which is the absolute pressure at the suction port—must always be greater than the pump's NPSHr. A common rule of thumb is to ensure a safety margin where NPSHa exceeds NPSHr by at least 3 to 5 feet. The NPSHr value is not constant; it increases as the flow rate increases, as shown by its upward-sloping curve.

Power Consumption: How Much Energy Does Your Pump Need?

The power consumption curve, often labeled as Brake Horsepower (BHP) or simply power, shows the amount of energy the pump requires from the motor to operate at a given point on its performance curve. This is typically represented by a dashed line and measured in horsepower (hp) or kilowatts (kW).

For most standard centrifugal pumps, the power required increases as the flow rate increases. This relationship is crucial for two reasons:

- Motor Sizing: You must select a motor that can provide sufficient power for the pump's entire potential operating range, not just the design point. This prevents the motor from overloading if system conditions change and cause the pump to operate at a higher flow rate.

- Energy Cost Calculation: The power curve allows you to predict the energy consumption of the pump at its expected operating point, which is essential for calculating a system's long-term operational costs.

Understanding this curve helps in making an energy-efficient choice, as a pump requiring less BHP for the same duty point will be more economical to run.

Efficiency: Getting the Most Out of Your Pump

The pump efficiency curve shows how effectively the pump converts the motor's energy into useful fluid movement (flow and head). It is typically represented by a series of half-moon or iso-efficiency lines on the chart, with percentages indicating the efficiency level. No pump is 100% efficient, as some energy is always lost to friction and turbulence.

The most important feature of this curve is the Best Efficiency Point (BEP), which is the peak of the efficiency curve. This point represents the flow rate and head at which the pump operates most economically and with the least amount of vibration and wear.

Operating a pump as close to its BEP as possible provides several key benefits:

- Maximizes energy savings and reduces operational costs.

- Extends the lifespan of components like seals and bearings.

- Ensures smooth and quiet operation.

Conversely, operating a pump far from its BEP—either to the far left or far right of the curve—results in lower efficiency, higher power consumption, and increased stress on the pump, which can shorten its life.

Pump Speed: Understanding RPM's Impact

A pump's performance curve is generated at a specific rotational speed, measured in revolutions per minute (RPM). However, the speed of the motor can be changed, often with a variable frequency drive (VFD), which will dramatically alter the pump's performance. The relationship between speed, flow, head, and power is described by the Pump Affinity Laws.

These laws state:

- Flow Rate is directly proportional to the change in speed. If you reduce the speed by 50%, the flow rate is also reduced by 50%.

- Head (Pressure) is proportional to the square of the change in speed. If you reduce the speed by 50% (a factor of 0.5), the head is reduced to 25% of its original value (0.5² = 0.25).

- Brake Horsepower (BHP) is proportional to the cube of the change in speed. If you reduce the speed by 50%, the power required drops to just 12.5% of the original (0.5³ = 0.125).

Because of the significant impact on power consumption, using VFDs to adjust pump speed is a highly efficient method for controlling flow compared to using a throttle valve. Many manufacturers provide curves that show performance at different RPMs, allowing for flexible and efficient system design.

Reading a Pump Curve: A Step-by-Step Guide

Reading a pump curve accurately is a fundamental skill for anyone involved in fluid handling systems. It allows you to determine if a pump will meet your application's needs and how it will behave once installed. The process involves plotting your system's requirements onto the pump's performance graph to find the operating point.

Locating Your Operating Point: Where Your Pump Performs

A pump does not choose its own operating point; it is determined by the system in which it is installed. To find this point, you need to understand both the pump curve and the system curve.

Determine Your System Requirements: First, calculate the required flow rate and the Total Dynamic Head (TDH) for your specific system. The TDH represents the total resistance your pump must overcome.

Understand the System Curve: A system curve is a graphical representation of your system's head loss at various flow rates. It typically starts at the system's static head (at zero flow) and curves upward, as friction losses increase with higher flow.

Find the Intersection: The operating point is the single point where the system curve intersects the pump's head-flow (H-Q) curve. This intersection reveals the actual flow rate and head the pump will deliver in that specific system.

For example, if your system requires 100 GPM at 80 feet of head, you would find 100 GPM on the x-axis and draw a vertical line up. Then, find 80 feet on the y-axis and draw a horizontal line across. The point where these lines meet is your required duty point. You would then select a pump whose H-Q curve passes through or very near this point.

Understanding the Best Efficiency Point (BEP)

Once you've located the potential operating point, the next step is to evaluate its efficiency. The Best Efficiency Point (BEP) is the point on the pump's performance curve where it operates at its highest hydraulic efficiency. This is graphically represented as the peak of the efficiency curve.

Operating a pump close to its BEP is crucial for several reasons:

- Energy Efficiency: The pump converts the maximum amount of input power into useful work, minimizing wasted energy and reducing electricity costs.

- Reliability and Longevity: At the BEP, the hydraulic forces inside the pump are balanced, which minimizes vibration, noise, and wear on components like bearings and seals.

- Stable Operation: Pumps running at their BEP are more stable and less prone to issues like recirculation or cavitation.

When selecting a pump, you should aim for your operating point to fall within a range of approximately 70-120% of the BEP flow rate. Operating too far to the left (low flow) or right (high flow) of the BEP can lead to premature failure and high maintenance costs.

Interpreting Impeller Trim and Its Influence

Most centrifugal pump casings are designed to accommodate impellers of several different diameters. Impeller trimming is the process of machining an impeller to reduce its outside diameter. This is a common and permanent method used to adjust a pump's performance to precisely match a system's required duty point.

Pump curves often display multiple H-Q curves on the same chart, each corresponding to a different impeller diameter (or "trim"). The top curve usually represents the maximum impeller diameter, while the lower curves show the performance for progressively smaller trims.

The effect of trimming an impeller can be predicted by the Affinity Laws for diameter changes:

- Flow (Q) is directly proportional to the impeller diameter.

- Head (H) is proportional to the square of the diameter.

- Power (P) is proportional to the cube of the diameter.

Reducing the impeller diameter lowers the pump's flow rate, head, and power consumption. While this is a cost-effective way to customize performance, it's important to note that trimming an impeller can also slightly reduce the pump's overall efficiency, especially with larger trims, because it increases the clearance between the impeller and the pump casing.

The Minimum Flow Line and Why It Matters for Pump Health

Operating a centrifugal pump at an extremely low flow rate, far to the left of its BEP, can be very damaging. To prevent this, manufacturers specify a Minimum Continuous Stable Flow (MCSF). This is the lowest flow rate at which the pump can operate continuously without experiencing issues like severe vibration, high temperatures, or internal recirculation.

Problems associated with operating below the MCSF include:

- Overheating: At very low flows, most of the energy put into the pump is converted into heat rather than fluid movement, which can cause the liquid to flash to vapor.

- Recirculation: Fluid can begin to recirculate within the pump casing and impeller, causing unstable pressure pulsations, vibration, and cavitation-like damage.

- High Bearing and Seal Loads: The unbalanced hydraulic forces at low flow can put extreme radial thrust on the pump shaft, leading to premature failure of bearings and mechanical seals.

The pump curve may indicate the MCSF with a vertical line or specific notation. It is critical to ensure your system design allows the pump to always operate above this minimum flow to ensure a long and reliable service life.

Factors Affecting Pump Performance and Curve Interpretation

A standard pump curve is created under specific test conditions, typically using clean water at a standard temperature. When the actual fluid being pumped has different properties, or when the operating temperature changes, the pump's performance will deviate from what is shown on the curve. Understanding how factors like specific gravity, viscosity, and temperature affect performance is crucial for accurate pump selection and system design.

Specific Gravity: When Your Liquid Isn't Just Water

Specific gravity (SG) is the ratio of a liquid's density to the density of water. Since water has an SG of 1.0, a liquid with an SG of 1.2 is 20% denser than water, while a liquid with an SG of 0.8 is 20% less dense.

The effect of specific gravity on a centrifugal pump's performance is straightforward:

- Head and Flow: A pump's ability to generate head (in feet or meters) and flow is not affected by the specific gravity of the liquid. The H-Q curve remains the same because the pump imparts the same velocity to the fluid, regardless of its weight.

- Pressure: The discharge pressure will change in direct proportion to the specific gravity. A denser fluid (higher SG) will result in a higher discharge pressure for the same head.

- Power Consumption (BHP): The brake horsepower required to drive the pump is directly proportional to the specific gravity. Pumping a fluid with an SG of 1.5 will require 50% more power than pumping water at the same flow and head.

Therefore, when pumping liquids other than water, the H-Q curve can still be used for selection, but the power consumption must be corrected by multiplying the BHP shown on the curve by the fluid's specific gravity. This is critical for ensuring the motor is not undersized.

Fluid Property |

How It Affects the Pump Curve | Practical Implication |

|---|---|---|

| Specific Gravit y | Head and Flow remain the same. Pressure and BHP change proportionally. | A higher SG requires a more powerful motor to avoid overload. The H-Q curve is still valid for selection. |

| Viscosity | Head, Flow, and Efficiency decrease. BHP increases significantly. | A standard centrifugal pump is not suitable for highly viscous fluids. Correction factors or a different pump type (like a Positive Displacement pump) are needed. |

| Temperature | Affects viscosity, vapor pressure (NPSH), and can cause material expansion/corrosion. | High temperatures increase cavitation risk and may require special materials of construction or cooling systems to ensure reliability. |

Viscosity: Pumping Thicker Fluids

Viscosity is a measure of a fluid's resistance to flow—in simple terms, its "thickness". Honey, for example, is much more viscous than water. Pumping highly viscous fluids has a significant and negative impact on the performance of a centrifugal pump.

Here’s how increased viscosity affects the pump's performance curves:

- Reduced Head and Flow: The increased internal friction (shear) of a thick fluid causes a dramatic reduction in the head and flow rate the pump can deliver. The H-Q curve will shift downwards and to the left.

- Increased Power Consumption: The pump has to work much harder to move a thicker fluid, resulting in a substantial increase in the brake horsepower (BHP) required.

- Decreased Efficiency: The combined effect of reduced output and increased power input leads to a sharp drop in pump efficiency.

Because of these negative effects, standard centrifugal pump curves are not directly usable for viscous fluids. Performance must be adjusted using correction charts provided by organizations like the Hydraulic Institute. For fluids with high viscosity, a positive displacement pump is often a more efficient and reliable choice as it is less affected by viscosity changes.

Temperature: Its Role in Pump Operation

Temperature plays a critical role in pump performance because it influences the properties of the fluid being pumped and the mechanical components of the pump itself.

Key effects of temperature include:

- Changes in Fluid Properties:

- Viscosity: For most liquids, viscosity decreases as temperature increases. Heating a thick oil, for instance, makes it easier to pump, which can improve efficiency and reduce power consumption. Conversely, pumping a fluid at a lower temperature than intended can increase its viscosity and overload the motor.

- Vapor Pressure: A liquid's vapor pressure increases significantly with temperature. This is critical for suction conditions, as a higher vapor pressure reduces the Net Positive Suction Head Available (NPSHa), increasing the risk of cavitation.

- Mechanical Effects:

- Thermal Expansion: Pump components, particularly those made of metal, expand when heated. Uneven expansion can cause parts to misalign or seize, leading to catastrophic failure. Materials must be selected to handle the expected operating temperatures.

- Corrosion: Higher temperatures can accelerate corrosion rates, especially when handling aggressive chemicals. This requires careful selection of corrosion-resistant materials for the pump.

- Component Life: Excessive heat can degrade seals and reduce the lifespan of bearings, leading to leaks and mechanical failures.

Due to these factors, it is crucial to consider both the fluid temperature and the ambient environmental temperature when selecting a pump to ensure long-term reliability.

Centrifugal vs. Positive Displacement Pumps: A Brief Comparison

While this guide focuses on centrifugal pump curves, it's important to recognize that they are not the only type of pump available. The other major category is the positive displacement (PD) pump. The choice between these two types depends heavily on the application's requirements, particularly concerning flow rate, pressure, and fluid viscosity.

When to Choose a Centrifugal Pump

Centrifugal pumps are the most common type used in a wide variety of industries. They use a rotating impeller to impart velocity to a fluid, moving it through the system. Their performance is characterized by a variable flow rate that depends on the system pressure (head), as shown on their pump curve.

Choose a centrifugal pump for:

- High Flow, Low-to-Moderate Head Applications: They are ideal for moving large volumes of liquid at relatively low pressures, such as in water supply, circulation systems, and general fluid transfer.

- Low-Viscosity Fluids: Centrifugal pumps perform best with thin liquids like water, light oils, and chemicals. Their efficiency drops dramatically with increasing viscosity.

- Applications Where Flow Can Vary: Since their flow rate naturally adjusts to changes in system head, they are well-suited for systems where precise flow is not a critical requirement.

- Cost-Effective and Simple Operation: They generally have a simpler design, lower initial cost, and require less maintenance compared to PD pumps.

When to Opt for a Positive Displacement Pump

Positive displacement pumps work by trapping a fixed volume of fluid and forcing (displacing) it into the discharge pipe. This mechanism results in a performance characteristic that is fundamentally different from a centrifugal pump. The flow rate of a PD pump is directly proportional to its speed (RPM) and is largely unaffected by changes in system pressure.

Choose a positive displacement pump for:

- High-Pressure Applications: PD pumps can generate very high pressures, often far exceeding the capabilities of a similar-sized centrifugal pump.

- Constant, Precise Flow: They are ideal for applications requiring a steady, metered flow, such as dosing, injection, and sampling. Their flow remains nearly constant even if the system pressure fluctuates.

- High-Viscosity Fluids: PD pumps are the go-to choice for handling thick, viscous fluids like heavy oils, slurries, syrups, and pastes. They can efficiently move fluids that would stop a centrifugal pump.

- Shear-Sensitive Liquids: Some PD pump designs, like lobe or peristaltic pumps, impart very low shear to the fluid, making them suitable for delicate products that can be damaged by the high-speed impeller of a centrifugal pump.

Frequently Asked Questions (FAQ)

1. What happens if I operate a pump far from its Best Efficiency Point (BEP)? Operating a pump significantly to the left or right of its BEP leads to inefficiency and mechanical stress. Operating to the left (low flow) can cause fluid recirculation within the pump, leading to overheating, pressure pulsations, and vibration. Operating to the right (high flow) can lead to cavitation, where low pressure creates vapor bubbles that collapse violently, eroding the impeller. Both conditions reduce the pump's lifespan and increase maintenance costs.

2. What is the difference between a pump curve and a system curve? A pump curve shows the performance capabilities of a pump (the head and flow it can produce). A system curve, on the other hand, represents the requirements of the piping system, showing the head needed to overcome static lift and friction at different flow rates. The actual operating point of the pump is where these two curves intersect.

3. Can I use a pump curve based on water for a different fluid? Yes, but with corrections. A standard pump curve is based on water. If your fluid has a different specific gravity, the flow and head on the curve remain the same, but the required power consumption (BHP) and resulting pressure will change proportionally. If the fluid is more viscous, the performance changes dramatically: head, flow, and efficiency will all decrease, while power consumption increases significantly. Correction factors are needed for accurate selection.

4. How does changing the pump's speed affect its performance? Changing a pump's speed with a Variable Frequency Drive (VFD) is a very effective way to control its output. According to the Affinity Laws, flow changes directly with speed, head changes by the square of the speed change, and power changes by the cube of the speed change. For example, reducing the speed to 80% will reduce flow to 80%, head to 64% (0.8²), and power demand to about 51% (0.8³), resulting in significant energy savings.

5. What is impeller trimming and why is it done? Impeller trimming is the physical machining of an impeller to reduce its outer diameter. This is done to permanently adjust a pump's performance to match a specific duty point that falls between standard impeller sizes. Trimming the impeller reduces the pump's head, flow, and power consumption, providing a customized solution without throttling the system with a valve.

Mastering the ability to read and understand pump curves is a skill that empowers us to make informed decisions about pump selection, system design, and operational optimization. It's truly everything you need to know to ensure efficient and reliable fluid handling. By paying close attention to the details presented in pump curves, we can not only prevent costly malfunctions but also ensure that our pumping systems operate at their peak performance, delivering the desired flow and head with maximum efficiency. We hope this guide has given you a comprehensive overview of pump curves and their importance.