Why Your Centrifugal Pump Runs Hot: Understanding Common Startup and Operation Issues

- Share

- Issue Time

- Oct 20,2025

Summary

Centrifugal pumps are vital in various industrial applications, but overheating can lead to reduced efficiency, costly repairs, and unexpected downtime. This comprehensive guide explores the common reasons behind pump overheating, categorizing them into operational errors, mechanical failures, and electrical problems, and offers solutions to ensure reliable operation. Key takeaways include recognizing that overheating often stems from multiple issues, the importance of early detection through vi

As someone who relies on centrifugal pumps, I understand that an overheating pump can be a major headache. Not only does it reduce efficiency, but it can also lead to costly repairs and unexpected downtime. In this guide, I'll explore t

Centrifugal pumps are crucial components in many industrial processes, from water treatment to chemical plants. When they overheat, it's a clear sign that something isn't right, potentially impacting performance and lifespan. Let's dive into the common startup and operation issues that cause centrifugal pumps to overheat and what we can do about them.

Key Takeaways

For operators and maintenance personnel looking for a quick summary, here are the critical points to remember about why your centrifugal pump is running hot:

- Multiple Root Causes: Overheating is rarely due to a single issue. It often stems from a combination of operational mistakes (like running the pump dry or against a closed valve), mechanical failures (worn bearings, seal issues), and electrical problems (low voltage, incorrect wiring).

- Early Detection is Crucial: Pay close attention to the early warning signs. These include unusual noises like grinding or rattling, a noticeable drop in flow rate or pressure, visible leaks around seals, and frequent motor trips. A pump casing that is excessively hot to the touch is a definitive red flag.

- Operational Point Matters: Operating a pump too far from its Best Efficiency Point (BEP) can cause significant problems. Running at very low flows (shut-off head) or excessive flows (run-out) leads to recirculation, cavitation, and vibration, all of which generate excess heat.

- Maintenance is Non-Negotiable: A proactive and consistent maintenance schedule is the best defense against overheating. This includes regular lubrication of bearings, inspection of seals and couplings, ensuring proper alignment, and keeping cooling systems clear and functional. Neglecting maintenance inevitably leads to costly failures.

- System Design is Foundational: The pump must be correctly matched to the system's requirements. An oversized or undersized pump will operate inefficiently, leading to chronic overheating and wear. Proper pipeline design, ensuring adequate suction head (NPSHa), and correct installation are fundamental to a healthy pumping system.

Recognizing the Common Startup and Operation Issues: Signs of an Overheating Centrifugal Pump

Before you can fix an overheating pump, you must first recognize the symptoms. An overheating pump rarely fails silently; it typically provides several visual, auditory, and performance-based clues that indicate a developing problem. Identifying these signs early is critical for preventing minor issues from escalating into catastrophic failures. These indicators can be broadly categorized into sensory cues and performance data.

Visual and Auditory Cues

The most immediate signs of trouble often come from what you can see and hear around the pump assembly. Your senses are the first line of defense in diagnostics.

Increased Temperature and Unusual Noise

The most obvious sign of an overheating pump is a surface temperature that is abnormally high. While it's normal for pump casings and motors to be warm during operation, they should not be too hot to touch safely for a few seconds. An infrared thermometer is an excellent tool for accurately monitoring the temperature of the pump casing, bearings, and motor. Any sudden spike or consistently high reading is a cause for concern.

Unusual noises are another primary indicator of distress. A healthy pump operates with a consistent, smooth hum. Sounds to watch out for include:

- Grinding or rumbling: This often points to failing bearings, which generate significant frictional heat.

- Rattling or sounds like marbles or gravel: This is a classic symptom of cavitation, a highly destructive condition that generates intense localized heat and vibration.

- High-pitched squealing or whining: This can indicate issues with bearings, mechanical seals, or rubbing between rotating and stationary parts.

Reduced Flow, Pressure, or Leakage

A drop in performance is a significant symptom directly tied to the pump's health. If you notice that the pump is not delivering its expected flow rate or that the discharge pressure has decreased, it could be a sign that internal issues are causing both the performance loss and the overheating. For instance, internal wear on the impeller or casing increases clearances, causing fluid to recirculate within the pump. This recirculation is inefficient and generates heat.

Visible leakage is another critical visual cue. Look for drips or sprays of fluid, especially around the mechanical seal or stuffing box. A failing seal can leak the process fluid, but it can also lose its lubricating film, causing the seal faces to run dry. This creates intense localized heat that can damage the seal and surrounding components, and this heat often transfers to the pump shaft and bearings.

Performance and Electrical Indicators

Beyond what you can see and hear, the pump's operational data provides clear evidence of underlying problems. Monitoring electrical consumption and operational cycles can reveal issues that might not yet be physically apparent.

Frequent Shutdowns and Motor Overload

If the pump's motor is frequently tripping its thermal overload protector, it's a definitive sign that the system is drawing too much current. This excessive current draw is a direct contributor to motor overheating. The overload can be triggered by several factors related to the pump itself, such as:

- Increased mechanical resistance: Failing bearings or a rubbing impeller force the motor to work harder.

- Operating off the curve: Running the pump at a very high flow rate (known as "end of curve" or "runout") can overload the motor.

- High fluid viscosity: Pumping a liquid that is thicker or denser than specified requires more power, leading to overload and heat.

Frequent start-stop cycles also contribute to heat buildup. Each time a motor starts, it draws a large amount of inrush current. If this happens too often, the motor windings do not have sufficient time to cool down between cycles, leading to cumulative overheating and potential damage.

Unpacking the Common Startup and Operation Issues: Why Centrifugal Pumps Overheat

Understanding why a centrifugal pump overheats requires looking at the entire system—from the fluid it moves to the electricity that powers it. The causes can be grouped into three main categories: operational errors, mechanical failures, and electrical problems. Often, a single overheating event is the result of a combination of these factors.

Operational Missteps and Flow Restrictions

How a pump is operated has a direct impact on its temperature. Many overheating issues stem from running the pump outside of its intended design parameters.

Cavitation and Inadequate or Blocked Flow

Cavitation occurs when the pressure of the liquid at the pump's suction falls below its vapor pressure, causing vapor bubbles to form. These bubbles collapse violently as they move toward the higher-pressure region of the impeller, creating intense shockwaves, vibration, and localized heat. This process not only erodes the impeller and casing but also significantly contributes to the overall heating of the pump. Cavitation is often caused by:

- A blocked or clogged suction line or strainer.

- A suction line that is too long or has too small a diameter.

- Insufficient Net Positive Suction Head Available (NPSHa).

Similarly, any obstruction in the discharge line forces the pump to work harder against a higher back-pressure. This condition, known as operating near "shut-off," causes most of the energy to be converted into heat rather than fluid motion, leading to rapid overheating of the liquid trapped inside the pump.

Running at Small Flow or Dry Running

Operating a centrifugal pump at a very low flow rate, or against a closed discharge valve, is extremely dangerous. This condition forces the fluid inside the pump casing to recirculate continuously. The energy imparted by the impeller is converted directly into heat, quickly raising the fluid's temperature and pressure. This can cause the liquid to flash to vapor, leading to a situation similar to cavitation, and can result in catastrophic failure.

Dry running is even more severe. It occurs when there is no liquid in the pump. Without fluid to lubricate and cool the components, friction between the rotating parts (like mechanical seals and wear rings) generates immense heat almost instantly. This can destroy the mechanical seal, warp the casing, and seize the pump in a matter of minutes.

Overloading and Frequent Start-Stop Cycles

Overloading happens when the pump demands more power from the motor than it is rated for. A common cause is running the pump too far to the right on its performance curve, where the flow rate is highest. This "runout" condition can occur if there's a break in the discharge line or if the system resistance is much lower than anticipated. The motor will draw excessive current in an attempt to meet the demand, causing its windings to overheat.

Frequent starting and stopping of the pump motor can also lead to overheating. Electric motors draw a very high current during startup to overcome inertia. If the pump is cycled on and off too quickly, the motor windings don't have enough time to dissipate the heat generated during the start-up phase, leading to a gradual temperature rise and potential insulation damage.

Mechanical and System-Related Causes

The physical condition of the pump and its interaction with the connected piping system are primary sources of heat generation. Wear and tear, improper assembly, and system mismatch are common culprits.

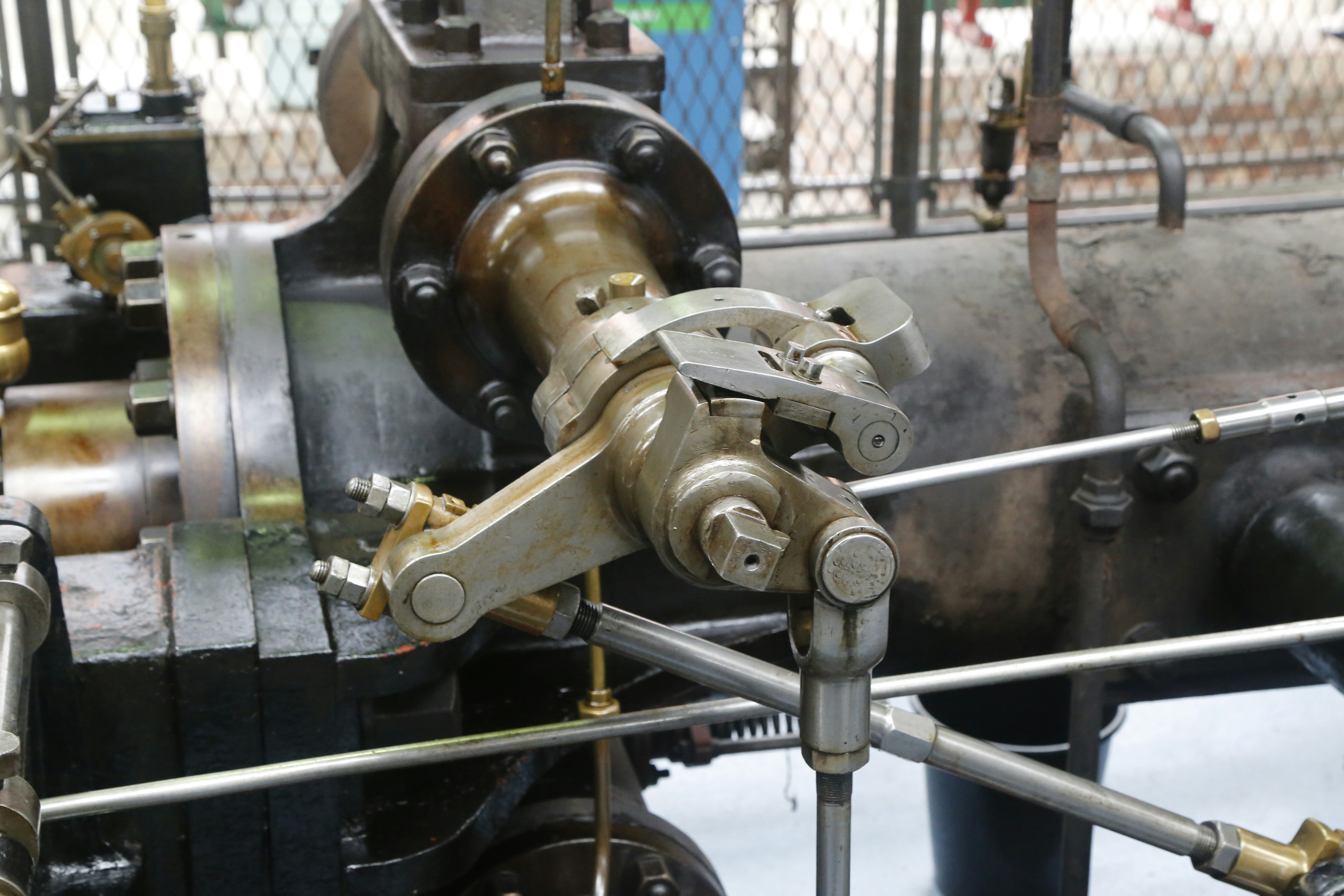

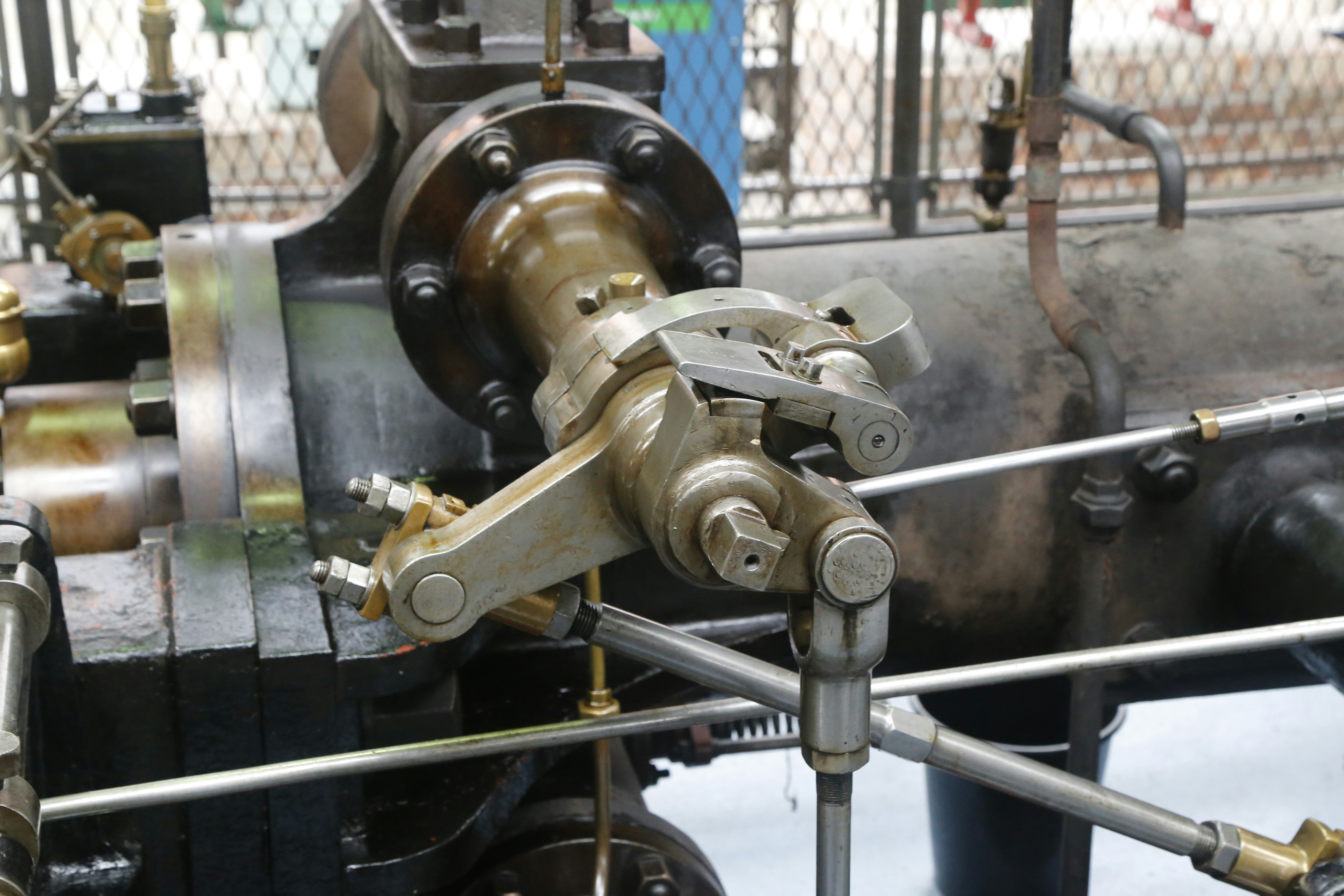

Bearing Issues and Mechanical Friction

Bearings are essential for supporting the pump shaft and allowing it to rotate smoothly. When they fail, they are a major source of frictional heat. Bearing failure can be caused by:

- Inadequate or improper lubrication: Too little, too much, or the wrong type of grease/oil can cause the bearings to overheat and fail.

- Contamination: Dirt, moisture, or other contaminants entering the bearing housing can lead to rapid wear.

- Misalignment: If the pump and motor shafts are not perfectly aligned, it places excessive radial and axial loads on the bearings, leading to premature failure and heat generation.

Any unintended contact between rotating and stationary parts, known as mechanical friction, will also generate heat. This can be caused by a bent shaft, incorrect impeller positioning, or worn components leading to improper clearances.

Sealing and Clearance Problems

Mechanical seals and packing are used to prevent fluid from leaking out along the pump shaft. A failing seal is a common source of heat. If the seal faces are not properly lubricated by the process fluid or a flush plan, they will rub against each other, creating intense frictional heat. This can damage the seal faces and elastomers, leading to seal failure and leakage.

Internal clearances, such as those between the impeller and the pump casing (wear rings), are also critical. If these clearances are too tight, they can cause rubbing and friction. If they are too loose due to wear, they allow excessive internal recirculation of the fluid. This recirculation is an inefficiency that churns the fluid and converts mechanical energy into heat, lowering the pump's efficiency and raising its temperature.

Pump-System Mismatch and Impeller Issues

Every pump is designed to operate most efficiently at a specific flow and pressure, known as the Best Efficiency Point (BEP). If the pump is not correctly matched to the system's requirements, it will operate away from its BEP, leading to inefficiency and potential problems. An oversized pump forced to run at a low flow rate will suffer from recirculation and high radial thrust, causing heat and vibration. An undersized pump will struggle to meet system demands, potentially running in an overload condition.

The impeller itself can also be a source of issues. An impeller that is trimmed to an incorrect diameter, is clogged with debris, or is made of a material unsuitable for the application can lead to inefficient operation and overheating.

Insufficient Cooling and Environmental Factors

Many pumps, and especially their motors, rely on cooling systems to dissipate the heat they generate. Motors often have a cooling fan that blows ambient air over cooling fins on the housing. If these fins are clogged with dirt and dust, or if the fan is damaged, the motor's ability to cool itself is compromised. Similarly, some pumps have cooling jackets or use external flush plans to cool the bearings or mechanical seal. A failure in these cooling systems will inevitably lead to overheating.

High ambient temperatures also play a significant role. A pump operating in a hot environment will have a harder time dissipating heat, making it more susceptible to overheating, especially when under heavy load.

Electrical and Wiring Common Startup and Operation Issues

The power supplied to the motor is the ultimate source of the pump's energy, and problems here can quickly manifest as heat.

Low Voltage and Wrong Wiring in Three-Phase Motors

A consistent and correct power supply is crucial for motor health. If the voltage supplied to the motor is lower than its rated voltage, the motor will have to draw more current to produce the required torque. This increased current leads to excessive heat in the motor windings (a relationship defined by the formula P = I²R), risking damage to the winding insulation. A voltage imbalance in a three-phase motor, where the voltages between the phases are not equal, will also cause a current imbalance, leading to overheating and vibration.

Incorrect wiring of a three-phase motor can also cause severe problems. For instance, if the phases are connected incorrectly, the motor may run in reverse. A centrifugal pump running backward will still pump some fluid but at a very low efficiency, which can lead to overheating of both the pump and motor.

Starting Overheating of Electric Motors

Some overheating issues are specific to the startup phase of the motor. If a motor overheats very quickly upon starting, it could point to several critical issues:

- A "jammed" or seized pump: If the pump's rotating assembly is stuck, the motor will try to turn it, drawing an extremely high current (locked-rotor amps) until its overload protection trips. This can generate heat very rapidly.

- Incorrect starting method: For large motors, using the wrong type of starter (e.g., direct-on-line when a soft starter is needed) can cause excessive electrical and mechanical stress during startup, leading to heat.

- Winding shorts: A short circuit within the motor windings can cause a massive current draw and immediate, localized overheating.

Addressing Common Startup and Operation Issues: Solutions for Overheating Pumps

When a centrifugal pump starts to overheat, a systematic approach to troubleshooting is essential to identify the root cause and apply the correct solution. Actions can be divided into immediate troubleshooting steps, long-term preventive measures, and potential system upgrades.

Immediate Actions and Troubleshooting Steps

If you detect an overheating pump, the first priority is to assess the situation and, if necessary, take the pump offline to prevent further damage.

Check and Adjust Operational Parameters

Before shutting down the pump (unless there is immediate danger), check its operating parameters.

- Verify Pressures: Check the suction and discharge gauges. Is the suction strainer clogged (indicated by unusually high vacuum)? Is the discharge valve throttled too much (indicated by excessively high pressure)?

- Confirm Flow Rate: Compare the current flow rate to the pump's performance curve. Is the pump operating far away from its BEP? Running near shut-off or in run-out conditions are primary causes of overheating.

- Examine the Fluid: If possible and safe, check the properties of the fluid being pumped. Has the temperature, viscosity, or specific gravity changed? Pumping a heavier or more viscous fluid than specified will increase the load on the motor.

Inspect Mechanical Components

If operational parameters seem normal, the next step is to inspect the mechanical health of the pump. This should be done after the pump has been safely shut down and locked out.

- Feel for Heat: Carefully check the temperature along the pump assembly. Is the heat concentrated at the bearings, the seal area, or the motor? An infrared thermometer is the best tool for this.

- Check Lubrication: Examine the oil level and condition in the bearing housing. Is the oil clean and at the correct level? If grease-lubricated, is there evidence of fresh grease?

- Inspect for Leaks: Look closely at the mechanical seal or packing for any signs of leakage.

- Rotate the Shaft: With the motor de-energized, try to rotate the pump shaft by hand. It should turn smoothly with minimal resistance. If it feels rough, gritty, or is difficult to turn, it points to bearing problems or internal rubbing.

Verify Electrical Connections and Voltage

Electrical issues are a frequent cause of motor overheating. A qualified electrician should perform these checks:

- Measure Voltage: Check the voltage at the motor terminals while it is running (if safe to do so) and compare it to the motor's nameplate rating. Low voltage is a common problem.

- Check Current Draw: Use a clamp-on ammeter to measure the current draw on all three phases. The readings should be balanced and below the full-load amp (FLA) rating on the nameplate. High or unbalanced amps indicate a problem.

- Inspect Wiring: Visually inspect all electrical connections for tightness and signs of corrosion or arcing.

| Troubleshooting Checklist | Potential Cause | Action |

|---|---|---|

| Symptom | Low Flow / High Pressure | Throttled discharge valve, blocked line |

| Observation | High motor amps, hot motor | Operate closer to BEP, check system for blockages |

| Symptom | Noise like gravel | Cavitation |

| Observation | Low suction pressure | Check suction strainer, increase suction head (NPSHa) |

| Symptom | Hot bearing housing | Lubrication failure, misalignment |

| Observation | Grinding noise, rough rotation | Check oil level/quality, perform laser alignment |

| Symptom | Motor trips on overload | Low voltage, high fluid viscosity |

| Observation | High current draw | Check supply voltage, verify fluid properties |

Preventive Measures and Best Practices

The most effective way to deal with overheating is to prevent it from happening in the first place. This is achieved through a robust maintenance program and adherence to best practices in installation and operation.

Regular Maintenance and Lubrication

A well-documented preventive maintenance (PM) program is your best defense against unexpected downtime. Key activities include:

- Scheduled Lubrication: Follow the manufacturer's recommendations for the type, amount, and frequency of lubrication for the bearings. Over-lubricating can be just as harmful as under-lubricating, as it can increase friction and heat.

- Vibration Analysis: Regularly monitor the pump's vibration signature. Changes in vibration can provide early warnings of bearing wear, misalignment, or imbalance long before they become critical.

- Seal Inspection: Regularly check the pump seal area for any signs of leakage. For pumps with seal flush plans, ensure the flush system is operating correctly.

- Motor Health Checks: Keep the motor cooling fins clean and ensure the cooling fan is operational. Periodically perform electrical tests like insulation resistance checks.

Proper Installation and System Design

A pump's life and reliability are determined before it is even turned on.

- Correct Sizing and Selection: Ensure the pump is correctly sized for the system's hydraulic requirements. A thorough analysis of the system curve is essential to ensure the pump operates at or near its BEP.

- Foundation and Alignment: The pump and motor must be mounted on a rigid, flat foundation. Crucially, the shaft alignment between the pump and driver must be precise. Laser alignment tools are the standard for achieving the required accuracy and minimizing stress on bearings and seals.

- Piping Design: Follow best practices for piping design. This includes keeping the suction piping as short and straight as possible, using eccentric reducers on horizontal suction lines to prevent air pockets, and installing pipe supports to eliminate strain on the pump casing.

Monitoring and Early Detection

Modern technology allows for continuous monitoring of pump health. Implementing condition monitoring systems can provide real-time data on temperature, vibration, and performance. These systems can alert operators to deviations from normal operating parameters, allowing for corrective action to be taken before a failure occurs. This proactive approach shifts maintenance from a reactive to a predictive model.

Upgrading Your Pump to Resolve Common Startup and Operation Issues

Sometimes, persistent overheating issues are a sign that the current pump is fundamentally wrong for the application.

When and How to Choose the Right Model

Consider upgrading or replacing your pump if:

- The pump consistently operates far from its BEP, leading to chronic issues.

- The process requirements have changed significantly since the original pump was installed.

- The pump is old, inefficient, and requires frequent, costly repairs.

When selecting a new pump, work with a qualified pump engineer or supplier to perform a complete system analysis. This involves calculating the total dynamic head (TDH) and required flow rate to select a pump that will operate efficiently within your system. Choosing a modern, high-efficiency model can also provide significant energy savings over the life of the pump, offering a rapid return on investment.

The Impact of Unresolved Common Startup and Operation Issues: Consequences of an Overheating Pump

Ignoring the warning signs of an overheating pump is a recipe for disaster. What might start as a minor temperature increase can cascade into a series of failures that impact your facility's productivity, budget, and safety. The consequences range from increased operational costs to catastrophic equipment failure and serious safety hazards.

Reduced Efficiency and Increased Costs

An overheating pump is an inefficient pump. The heat it generates is wasted energy that should have been used to move fluid. This directly translates to higher electricity consumption. For example, a pump suffering from severe internal recirculation might consume significantly more power while delivering less flow, causing a sharp spike in energy costs per gallon pumped.

Furthermore, allowing a pump to run hot leads to a cycle of escalating maintenance costs. The initial problem—such as poor lubrication—causes the bearings to run hot. This heat can then damage the mechanical seal. The vibration from the failing bearings can cause wear on the impeller and casing. Before long, a single component failure has led to a major overhaul, involving expensive replacement parts and significant labor costs.

Accelerated Wear and Catastrophic Failure

Heat is a primary enemy of mechanical components. Consistent overheating drastically shortens the lifespan of critical pump parts:

- Bearings: High temperatures degrade lubricant, leading to metal-to-metal contact and rapid wear. A bearing designed to last for years can fail in a matter of hours under severe overheating conditions.

- Mechanical Seals: The elastomers (O-rings) in a mechanical seal can become brittle and crack when exposed to excessive heat, leading to leakage. The precision-lapped seal faces can warp, causing them to open and fail completely.

- Motor Windings: The insulation on motor windings is rated for a specific temperature. Overheating degrades this insulation, which can lead to a short circuit between the windings and complete motor failure.

In the worst-case scenario, unresolved overheating can lead to catastrophic failure. For instance, if a pump running against a closed valve is left unattended, the liquid inside can boil, creating immense pressure. This can cause the pump casing to rupture violently, an event known as a "pump explosion," which can destroy the equipment and pose a severe threat to nearby personnel and infrastructure.

Safety Hazards and Environmental Risks

An overheating pump is not just a maintenance problem; it is a serious safety risk. The potential for a catastrophic casing rupture presents a clear danger to anyone in the vicinity. Furthermore, if the pump is handling a hazardous, flammable, or toxic liquid, a failure can have dire consequences.

A breach of containment caused by a failed seal or ruptured casing can result in:

- Fires or Explosions: If the leaking fluid is flammable and finds an ignition source.

- Toxic Exposure: Releasing harmful chemicals into the work environment, endangering employee health.

- Environmental Damage: Spills of chemicals or pollutants can lead to costly cleanup operations and regulatory fines.

Even a seemingly minor leak from an overheating seal can create a slippery floor, leading to slip-and-fall accidents. Therefore, addressing an overheating pump is a critical part of maintaining a safe and environmentally responsible workplace.

Frequently Asked Questions (FAQ)

Q1: How hot is too hot for a centrifugal pump? A: While it varies by manufacturer and application, a general rule of thumb is that the bearing housing temperature should not exceed 180-200°F (82-93°C). The motor casing temperature should typically not be more than 40°C above the ambient temperature. The most reliable method is to use a non-contact infrared thermometer and compare the readings to the manufacturer's specified limits. If any part of the pump is too hot to touch for more than a few seconds, it warrants immediate investigation.

Q2: Can running a pump against a closed valve for a short time cause damage? A: Yes, even a few minutes of operation against a dead-headed or closed discharge valve can cause significant damage. The energy from the motor is converted directly into heat, rapidly increasing the temperature and pressure of the trapped liquid. This can lead to mechanical seal failure, bearing damage, and in extreme cases, a violent rupture of the pump casing. It should be avoided at all costs.

Q3: What is the difference between cavitation and aeration? A: Both cause similar damage, but their origins differ. Cavitation occurs when the liquid's pressure drops below its vapor pressure, forming vapor bubbles. This is typically a suction-side problem related to insufficient NPSHa. Aeration occurs when external air or gas is drawn into the pump, often through a leak in the suction piping or a low liquid level in the source tank. Both conditions are destructive and cause noise, vibration, and performance loss.

Q4: How does motor voltage affect pump overheating? A: A motor's performance is highly dependent on receiving the correct voltage. If the supply voltage is too low, the motor must draw more current (amps) to produce the required horsepower. This excess current causes the motor windings to overheat, which can degrade the insulation and lead to motor failure. Conversely, excessively high voltage can also cause issues like increased magnetic flux, leading to saturation and overheating.

Q5: Is vibration always a sign of an overheating problem? A: Not always directly, but vibration and overheating are very often linked. Many problems that cause overheating—such as bearing failure, misalignment, cavitation, and operating off-BEP—also cause significant vibration. Therefore, an increase in vibration is a strong early indicator that a problem is developing which will likely lead to overheating if left unaddressed. Monitoring vibration is a key predictive maintenance technique.

By understanding and proactively addressing the common startup and operation issues that lead to centrifugal pump overheating, we can significantly extend the life of our equipment, reduce maintenance costs, and ensure reliable performance. Regular monitoring, proper maintenance, and swift troubleshooting are key to keeping our pumps running cool and efficient.

Ultimately, recognizing the signs, understanding the root causes, and implementing effective solutions for an overheating centrifugal pump are essential for any operation. My hope is that this guide empowers you to tackle these challenges head-on, ensuring the continued success and longevity of your pumping systems.