IY Single-Stage Pump | Horizontal Centrifugal Pump | Clear Water Pump | Industrial pump | oil pump

- Price

- US $800-600

- Model

- IY Single-Stage Pump

- MOQ

- 1 piece

Item specifics

- Power

- 0.55-110KW

- Capacity

- 6.3-400m3/h

- Max Head

- 5-125m

- Colour

- customizable

Review

Description

- Product Introduction

- Product Features

- Scope of Application

- Structural Drawings

- Performance Parameters

- Data Download

Product Introduction

The single-stage single-suction centrifugal pump is installed horizontally, with horizontal axial suction and upward radial discharge. During maintenance, the rotor components can be extracted for maintenance without disassembling the inlet and outlet pipelines. Shaft seals can use packing seals or mechanical seals. Pump materials are divided into ordinary cast iron, wear-resistant cast iron, cast steel, stainless steel, etc. The flow rate is 6.3-400m3/h. The lift is 5-125m. The medium temperature should not be higher than 80℃.

Model Description:

Take IY80-65J-160(A,B,C) as an example:

✔ IY: Single-suction single-stage oil transfer centrifugal pump

✔ 80: The diameter of the pump inlet is 80 (mm)

✔ 65: The diameter of the pump outlet is 65 (mm)

✔ J: Use at a reduced speed

✔ 160: Nominal diameter of the impeller

✔ (A, B, C): First, second and third impeller cuts.

Product Features:

- Compact structure: With a reasonable design, it occupies a small area and is easy to install.

- High efficiency and energy saving: Adopting an advanced hydraulic model, it has high efficiency and low energy consumption.

- Smooth operation: The impeller has undergone precise balance correction, resulting in low vibration and low noise.

- Easy maintenance: The pump shaft and motor are on the same axis, making disassembly and assembly convenient and reducing maintenance costs.

- Reliable sealing: Equipped with mechanical seals or packing seals to ensure no leakage and reliable operation.

Scope of Application:

It is suitable for industrial and urban water supply and drainage, pressurized water supply of high-rise buildings, garden sprinkler irrigation, fire pressurization, long-distance water supply, heating, bathroom and other cold and warm water circulation pressurization

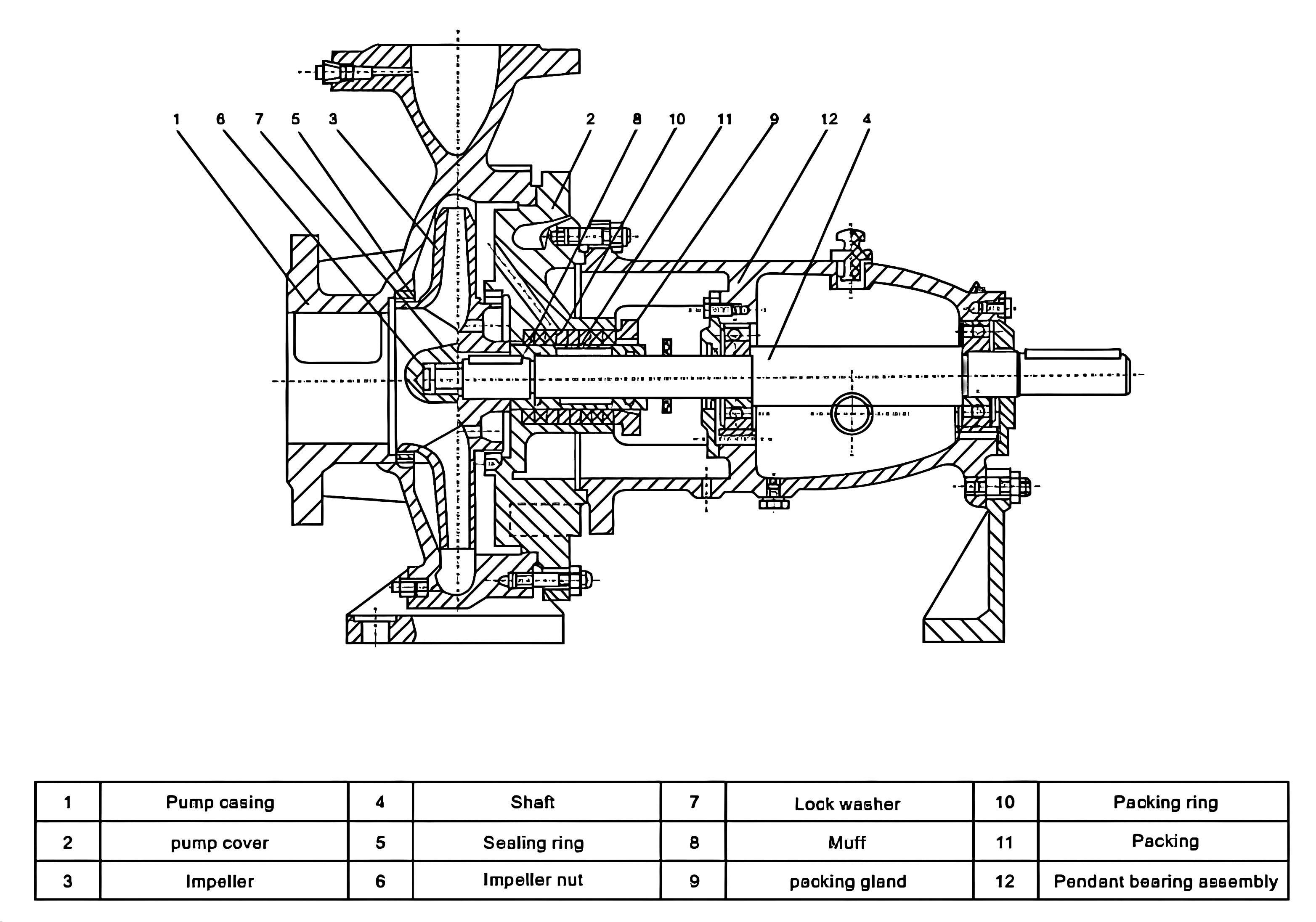

Structural Drawings:

Structural Drawings:

Performance Parameters:

Performance Parameters:

NO. | Model | Flow Rate | Head | Speed | Efficiency | (NPSH)r | Motor Power | Shaft power | Impeller diameter D2 | Weight |

IY | m3/h | m | rpm | % | m | kW | kW | mm | kg | |

1 | 50-32-160 | 12.5 | 32 | 2900 | | 2.0 | 3 | 2.02 | 158 | 40 |

2 | 65-50-160 | 25 | 32 | 2900 | 2.0 | 5.5 | 3.35 | 165 | 39 | |

3 | 80-65-125 | 50 | 20 | 2900 | | 3.0 | 5.5 | 6.63 | 137 | 53.5 |

4 | 80-65-160A | 46.8 | 28 | 2900 | 2.5 | 7.5 | 5.03 | 159 | 44 | |

5 | 100-80-125 | 100 | 20 | 2900 | 4.5 | 11 | 7.00 | 139 | 58 | |

6 | 100-65-200 | 100 | 50 | 2900 | 3.6 | 22 | 17.9 | 203 | 86 | |

7 | 100-65-250A | 93.5 | 70 | 2900 | 3.8 | 30 | 25.5 | 241 | 95 | |

8 | 125-100-200 | 200 | 50 | 2900 | 4.5 | 45 | 33.6 | 216 | 87 | |

9 | 150-125-400 | 200 | 50 | 1450 | 2.8 | 45 | 36.3 | 339.5 | 187 | |

10 | 200-150-315 | 400 | 32 | 1450 | 3.5 | 55 | 42.5 | 350 | 168 | |

11 | 200-150-400 | 400 | 50 | 1450 | 3.8 | 90 | 67.2 | 395 | 186 | |

... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... |

*For more models, please download our catalogue or contact us.

Data Download:

Data Download:

IS Single-Stage PumP