DG Horizontal Multistage Centrifugal Water Pump | Heat Pump | Water Boiler Pump | High Temperature

- Price

- US $2600-2000

- Model

- DG

- MOQ

- 1 piece

Item specifics

- Material

- Cast iron, cast steel, stainless steel

- Capacity

- 3.75-840m3/h

- Max Head

- 19-680m

- Colour

- customizable

Review

Description

- Product Introduction

- Product Features

- Scope of Application

- Structural Drawings

- Performance Parameters

- Data Download

Product Introduction

The DG type boiler feed water pump is a multi-stage centrifugal pump, specially designed for boiler feed water systems. It is widely used in the boiler water supply systems of industries such as power, chemical, metallurgy, and textile. This pump features high efficiency, stability, and durability, and can meet the water supply requirements under high-temperature and high-pressure working conditions.

Main uses: Power plant boiler feed water, industrial boiler feed water, urban water supply systems, and other occasions requiring high-pressure feed water.

Model Description:

For example: DG 85-45×7

✔ DG: Multi stage boiler feed pump

✔ 85: The rated flow rate of the water pump is 85 m³/h

✔ 45: Design point single-stage head is 45 m

✔ 7 : Number of stages is 7 stages

Product Features:

- High efficiency and energy saving: Advanced hydraulic model design ensures high efficiency, low energy consumption and economical operation.

- Compact structure: Multi-stage segmented design results in small volume, less floor space, and convenient installation and maintenance.

- Resistance to high temperature and high pressure: The pump body and flow-through components are made of high-quality materials, capable of withstanding high-temperature and high-pressure working conditions, ensuring long-term stable operation.

- Smooth operation: The rotor components undergo precise dynamic balance correction, resulting in low vibration, low noise, and reliable smooth operation.

- Excellent sealing performance: Mechanical seals or packing seals are adopted, featuring superior sealing performance, minimal leakage, and long service life.

- Strong adaptability: Different numbers of stages, flow rates and head can be customized according to user requirements, meeting various working conditions.

Scope of Application:

- Power plant boiler feed water

- Industrial boiler feed water

- Urban water supply system

- Other occasions requiring high-pressure feed water

Supporting services: "Customization Available", "1-Year Warranty", "Technical Drawing Provided"

Supporting services: "Customization Available", "1-Year Warranty", "Technical Drawing Provided"

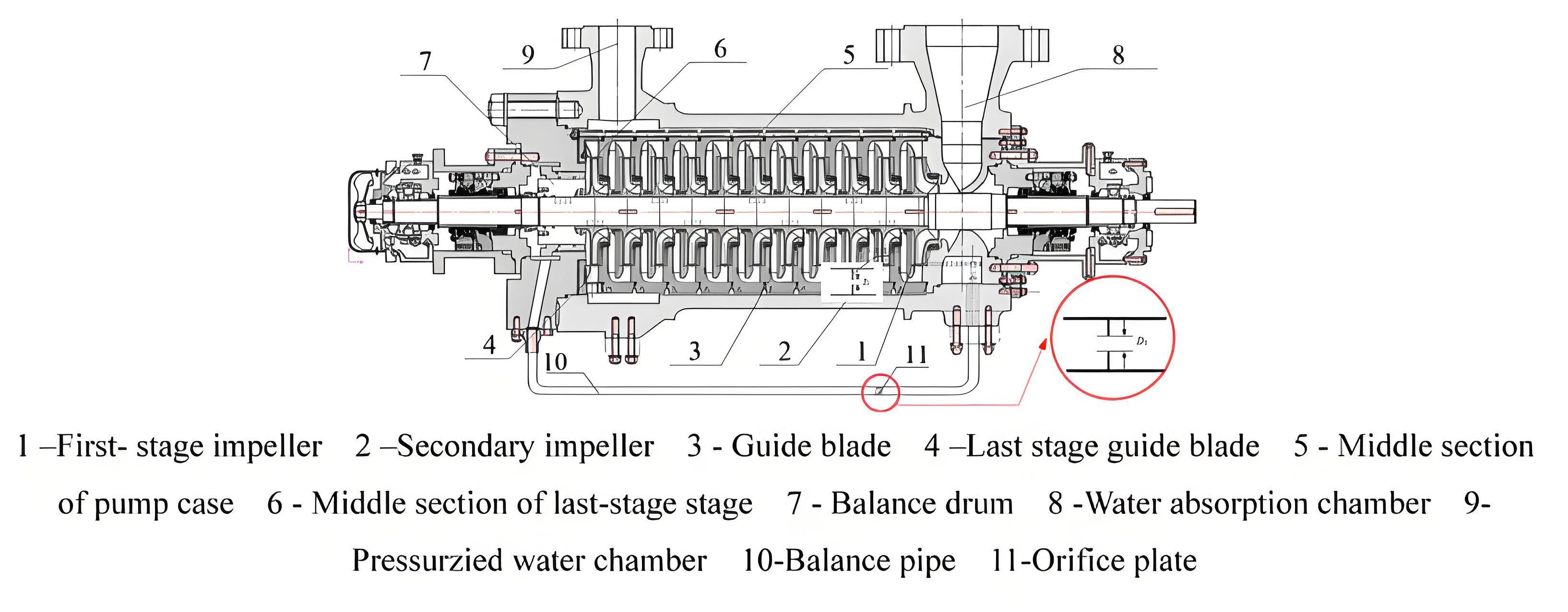

Structural Drawings:

Structural Drawings:

Performance Parameters:

Performance Parameters:

NO. | Model | Flow Rate | Head | Speed | Efficiency | (NPSH)r | Motor Power | Inlet Diameter | Outlet Diameter | Weight | |

DG | m3/h | L/s | m | rpm | % | m | kW | mm | mm | kg | |

1 | 6-50×2 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 104 100 96 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 11 | 50 | 50 | 142 |

2 | 6-50×3 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 156 150 144 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 15 | 50 | 50 | 156 |

3 | 6-50×4 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 208 200 192 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 18.5 | 50 | 50 | 170 |

4 | 6-50×5 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 260 250 240 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 22 | 50 | 50 | 184 |

5 | 6-50×6 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 312 300 288 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 30 | 50 | 50 | 197 |

6 | 6-50×7 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 364 350 336 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 30 | 50 | 50 | 211 |

7 | 6-50×8 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 416 400 384 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 37 | 50 | 50 | 225 |

8 | 6-50×9 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 468 450 432 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 37 | 50 | 50 | 238 |

9 | 6-50×10 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 520 500 480 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 45 | 50 | 50 | 252 |

10 | 6-50×11 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 572 550 528 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 45 | 50 | 50 | 265 |

11 | 6-50×12 | 3.75 6.3 7.5 | 1.04 1.75 2.08 | 624 600 576 | 2950 | 28 30 29 | 3.0 3.0 3.5 | 55 | 50 | 50 | 279 |

... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... |

*For more models, please download our catalogue or contact us.

Data Download:

Data Download:

DG Multi stage boiler feed pump