Horizontal Stage Centrifugal Water Pump | High Efficiency | Stainless steel chemical pump | Cost Effective

- Model

- ZE

Item specifics

- Power

- 0.55-110KW

- Capacity

- 6.3-400m3/h

- Max Head

- 5-125m

- Colour

- customizable

Review

Description

- Product Introduction

- Product Features

- Scope of Application

- Structural Drawings

- Performance Parameters

- Data Download

Product Introduction

The ZE type chemical pump is a single-stage single-suction centrifugal pump, specially designed for transporting corrosive media. This pump is made of stainless steel or other corrosion-resistant materials, featuring excellent corrosion resistance. It is widely used in industries such as chemical engineering, petroleum, pharmaceuticals, food, and metallurgy for transporting corrosive liquids like acids, alkalis, and salts. Its temperature range is from -20℃ to 120℃.

Model Description:

Take ZE50-32-160 as an example:

- ZE: Chemical pump type

- 50: Pump inlet diameter (mm)

- 32: Pump outlet diameter (mm)

- 160: Impeller nominal diameter (mm)

Product Features:

- Strong corrosion resistance: Made of stainless steel or other corrosion-resistant materials, suitable for various corrosive media.

- Compact structure: Reasonable design, small footprint, easy installation.

- High efficiency and energy saving: Advanced hydraulic model, high efficiency, low energy consumption.

- Smooth operation: The impeller is precisely balanced, with low vibration and low noise.

- Easy maintenance: The pump shaft and motor are on the same axis, easy to disassemble and assemble, and low maintenance cost.

- Reliable sealing: Equipped with mechanical seals or packing seals to ensure no leakage and reliable operation.

Scope of Application:

- Chemical industry: Used for transporting corrosive liquids such as acids, alkalis, and salts.

- Petroleum industry: Used for transporting crude oil, refined oil products, and chemical raw materials.

- Pharmaceutical industry: Used for transporting pharmaceutical solutions, solvents, etc.

- Food industry: Used for transporting beverages, dairy products, etc.

- Metallurgical industry: Used for transporting pickling solutions, electrolytes, etc.

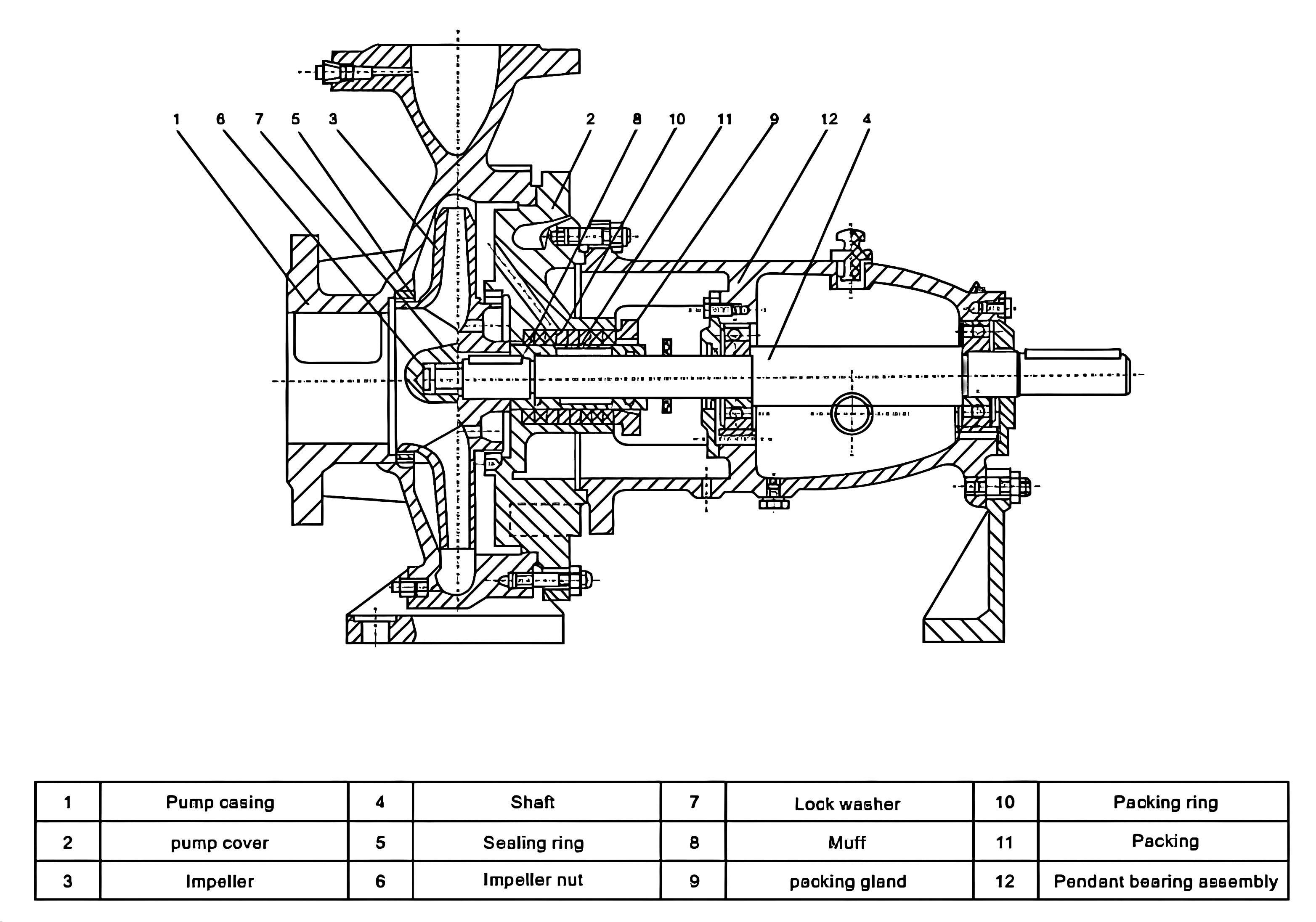

Structural Drawings:

Structural Drawings:

Performance Parameters:

Performance Parameters:

NO. | Model | Flow Rate | Head | Speed | Efficiency | (NPSH)r | Motor Power | Inlet Diameter |

ZE | m3/h | m | rpm | % | m | kW | mm | |

1 | 32-25-160 | 6 | 33 | 2900 | 22.45 | 2.0 | 3.0 | 2.4 |

2 | 50-32-160 | 12.5 | 32 | 2900 | 38 | 2.0 | 4 | 2.83 |

3 | 50-32-200 | 6 | 60 | 2900 | 39 | 3.0 | 7.5 | 2.5 |

4 | 65-50-205 | 25 | 80 | 2900 | 46 | 2.0 | 15 | 11.8 |

5 | 80-65-125 | 50 | 20 | 2900 | 52 | 2.3 | 7.5 | 5.2 |

6 | 80-65-250 | 50 | 80 | 2900 | 50 | 2.5 | 22 | 21.77 |

7 | 100-80-160 | 100 | 32 | 2900 | 61 | 4.3 | 15 | 14.32 |

8 | 100-80-200 | 100 | 50 | 2900 | 72 | 3.9 | 22 | 18.9 |

9 | 125-100-200 | 200 | 50 | 2900 | 70 | 5 | 45 | 38.9 |

10 | 125-100-315 | 120 | 32 | 1450 | 58 | 3.0 | 22 | 18 |

11 | 150-125-250 | 200 | 20 | 1450 | 70 | 3.0 | 18.5 | 15.6 |

12 | 150-125-315 | 200 | 32 | 1450 | 68 | 3.0 | 30 | 25.6 |

13 | 200-150-250 | 400 | 20 | 1450 | 60 | 5 | 37 | 36.3 |

14 | 200-150-315 | 350 | 100 | 2900 | 48 | 5 | 200 | 198.5 |

... | ... | ... | ... | ... | ... | ... | ... | ... |

*For more models, please download our catalogue or contact us.

Data Download:

Data Download:

ZE-type Multistage Pump