GW sewage pump | submersible centrifugal pump | Transport media such as sewage, sludge and wastewater

- Price

- US $800-600

- Model

- GW Sewage Pump

- MOQ

- 1 piece

Item specifics

- Colour

- customizable

- Capacity

- 3.75-840m3/h

- Max Head

- 19-680m

Review

Description

- Product Introduction

- Product Features

- Scope of Application

- Structural Drawings

- Performance Parameters

- Data Download

Product Introduction

The GW type sewage pump is a submersible centrifugal pump designed for transporting media such as sewage, sludge, and wastewater containing solid particles and fibers. This pump features high efficiency, wear resistance, and corrosion resistance, and is widely used in municipal engineering, sewage treatment, construction sites, mine drainage, agricultural irrigation, and other fields. Its operating temperature range is from -20℃ to 60℃.

Model Description:

Take GW50-20-15 as an example:

- GW: Sewage pump type

- 50: Pump outlet diameter (mm)

- 20: Flow rate (m³/h)

- 15: Head (m)

Product Features:

- Efficient sewage discharge: With a unique impeller design, it can effectively convey sewage containing solid particles and fibers.

- Wear-resistant and corrosion-resistant: The pump body and impeller are made of high-chromium alloy materials, which have excellent wear resistance and corrosion resistance.

- Compact structure: The design is reasonable, with a small footprint and easy installation. Smooth operation: The impeller has undergone precise balance correction, resulting in low vibration and low noise.

- Easy maintenance: The pump shaft is coaxial with the motor, making disassembly and assembly convenient and reducing maintenance costs.

- Reliable sealing: It adopts mechanical seals or packing seals to ensure no leakage and reliable operation.

Scope of Application:

- Municipal engineering: for urban drainage, sewage treatment and stormwater discharge.

- Construction sites: for foundation pit drainage and construction wastewater discharge.

- Mine drainage: for mine shaft drainage and sludge transportation.

- Agricultural irrigation: for farmland drainage and irrigation systems.

- Industrial wastewater: for factory wastewater and sludge discharge.

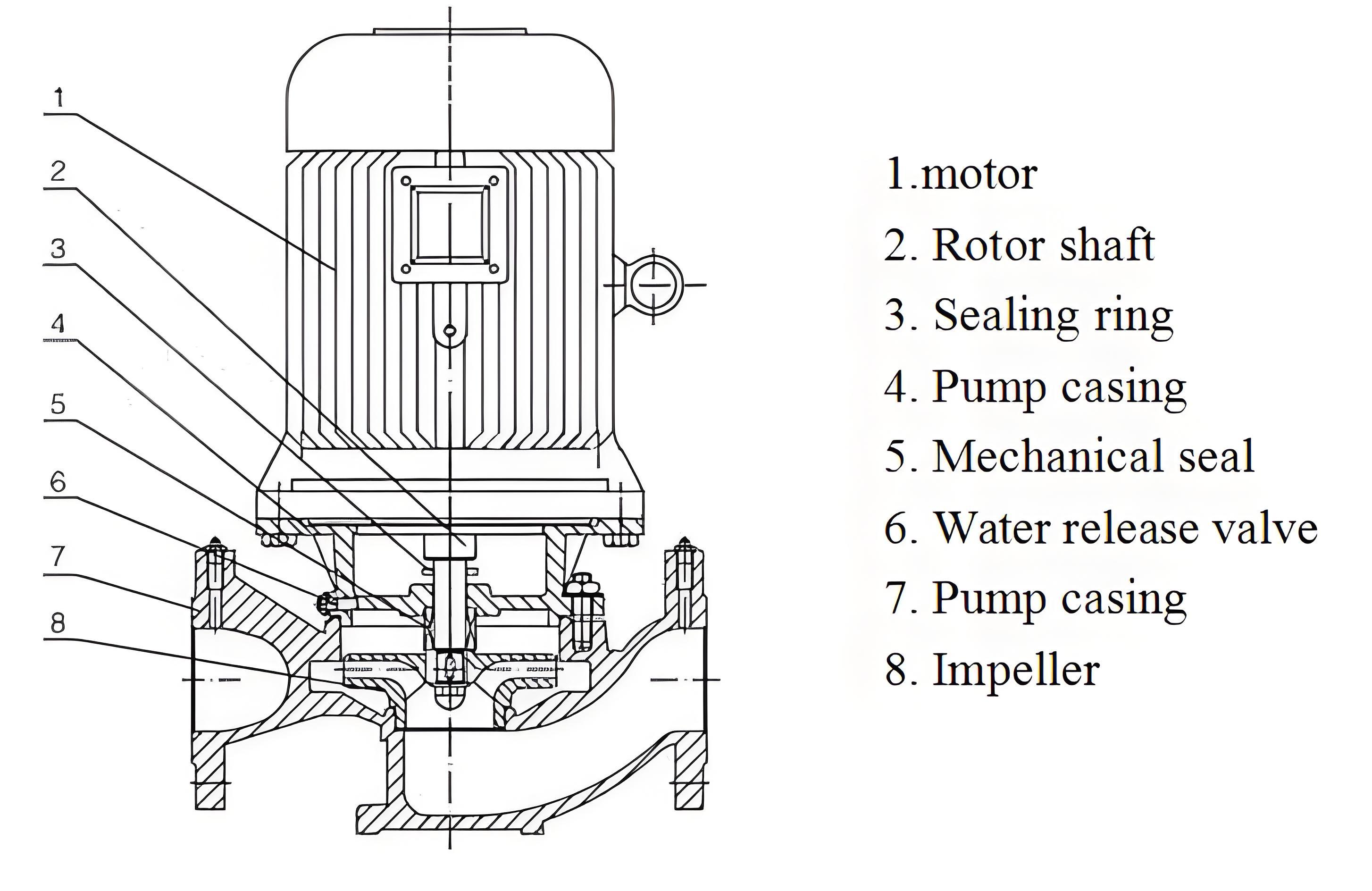

Structural Drawings:

Structural Drawings:

Performance Parameters:

Performance Parameters:

NO. | Model | Flow Rate | Head | Speed | Efficiency | Motor Power | Outlet Diameter | Weight | |

m3/h | m | rpm | % | kW | mm | kg | |||

1 | 25GW8-22-1.1 | 8 | 22 | 2900 | 38 | 1.1 | 25 | 42 | |

2 | 40GW15-15-1.5 | 15 | 15 | 2950 | 45 | 1.5 | 40 | 52 | |

3 | 50GW15-25-2.2 | 15 | 25 | 2950 | 56 | 2.2 | 50 | 60 | |

4 | 65GW30-40-7.5 | 30 | 40 | 2950 | 56 | 7.5 | 65 | 110 | |

5 | 80GW65-25-7.5 | 65 | 25 | 2950 | 56 | 7.5 | 80 | 135 | |

6 | 100GW100-25-11 | 100 | 25 | 1450 | 65 | 11 | 100 | 270 | |

7 | 125GW130-20-15 | 130 | 20 | 1450 | 63 | 15 | 125 | 300 | |

8 | 150GW180-30-30 | 180 | 30 | 1450 | 73 | 30 | 150 | 500 | |

9 | 200GW400-30-45 | 400 | 30 | 1480 | 70 | 45 | 200 | 1000 | |

10 | 250GW600-25-75 | 600 | 25 | 1480 | 73 | 75 | 250 | 1300 | |

11 | 300GW950-20-90 | 950 | 20 | 980 | 80 | 90 | 300 | 1700 | |

12 | 300GW1000-25-110 | 1000 | 25 | 980 | 82 | 110 | 300 | 2520 | |

13 | 350GW-1100-10-55 | 1100 | 10 | 980 | 84.5 | 55 | 350 | 2880 | |

14 | 350GW1500-15-90 | 1500 | 15 | 980 | 82.5 | 90 | 350 | 2250 | |

15 | 350GW1000-36-160 | 1000 | 36 | 740 | 78.5 | 160 | 350 | 2500 | |

16 | 400GW1500-10-75 | 1500 | 10 | 980 | 82.1 | 75 | 400 | 2580 | |

17 | 400GW2000-15-132 | 2000 | 15 | 740 | 85.5 | 132 | 400 | 2800 | |

... | ... | ... | ... | ... | ... | ... | ... | ... | |

*For more models, please download our catalogue or contact us.

Data Download:

Data Download:

GW-type Sewage pump